Home > PR Center >R&D

Based on the core technology of the world’s best powder and coating, the competitiveness of the existing business will be increased and COSMO AM&T Technology and Research Center focuses all its competence along with R & D investments in order to realize the new material development such as materials for display, secondary battery materials, materials for digital devices and others which are necessary for the customers. In the future, we will work towards taking a step closer to the customers through high value added product development.

Address: 36, Chungjuhosu-ro, Chungju-si, Chungcheongbuk-do TEL: 043) 850-1114 FAX: 043) 850-1359.

Release film adds silicon composites on one-sided or both-sided polyester base film and inorganic particles that show anti-static effects for outstanding efficiency in performance, internal blocking and adhesion

Release film of COSMO AM&T adds silicon composites and inorganic particles with anti-static effect on the one-side or both-sides of polyester film (PET) for excellent efficiency of in performance, internal blocking and adhesion. Once this is coated on the release films, it leads to uniform peeling strength, residual adhesion and extremely outstanding anti-static performance.

- Application

- This release film has moderate surface illumination intensity and thickness uniformity and its excellent application in various purposes and process conditions allows it to be used in temporary supporter and adhesion level protection of industrial, adhesive objects. It is used as carrier film when forming resin sheet or ceramic sheet and others.

- Structure

-

The adhesive film of COSMO AM&T can be categorized into products for manufacturing and products for electronic appliances. The products for manufacturing semi-conductor are comprised of Back Side Tape and Dicing Tape for semi-conductor package manufacture. In the case of Back Side Tape, the low molecular siloxane is effectively reduced through the unique technology of our company, resolving the out-gassing problems that occur during the manufacturing process of semi-conductor package. In the case of Dicing Tape, as photo-curable type, it has high adhesion when cutting the package and with effective reduction in adhesion after photo-curing, it has optimized the Chip Pick up characteristics. The products for electronic appliances involves the development of ultra slim tape which can be used in mobile electronic appliances. The obscuration effects can be applied according to the usage purpose and is effective in maintaining the durability in high temperature and high humidity conditions.

- Application

- The adhesive film of COSMO AM&T is applied in semi-conductor manufacturing industry, electrical and electronic industry

- Structure

-

Cathode materials, as core material for secondary batteries are a material that plays the core role in the charge and discharge of batteries. The secondary battery market ($ 4 billion/year) is rapidly growing and requires secondary batteries that are lighter and with high capacity. The most important material out of the factors that determine the characteristics of the secondary battery is the cathode material.

The main material of cathode material is lithium cobalt oxide (LiCoO2) and is a material with high capacity, long lifespan and outstanding safety. COSMO AM&T has completed the development of LiCoO2 that is used in the current commercialization and is in the midst of developing an active material with a higher level of high voltage, high performance characteristics.

The main material of cathode material is lithium cobalt oxide (LiCoO2) and is a material with high capacity, long lifespan and outstanding safety. COSMO AM&T has completed the development of LiCoO2 that is used in the current commercialization and is in the midst of developing an active material with a higher level of high voltage, high performance characteristics.

- Application

- It is widely used in digital mobile devices such as hand phones, digital cameras, MP3s, electric tool and in secondary batteries for vehicles (HEV).

- Structure

-

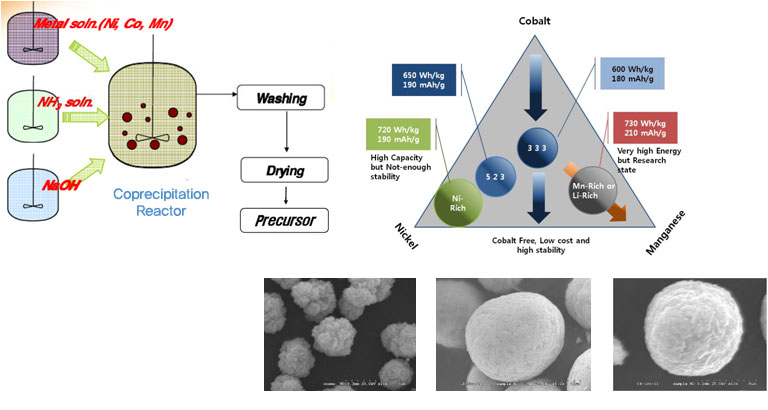

Development of cathode material precursor for secondary batteries

- Purpose of product

- As raw material of cathode material for lithium secondary batteries, it becomes cathode material by being mixed with lithium raw material. There are Co3O4, Co(OH)2, CoOOH in the precursor of LiCoO2 and for the precursor of Li(NixCoyMnz)O2, NixCoyMnz(OH)2 is mainly used.

- Manufacturing method

-

It is mainly manufactured with co-precipitation method and chemical reactor is used to create co-precipitation reaction such as metal mixture solution, caustic soda, ammonia and others for manufacturing. Various products can be manufactured according to the reaction methods (composition, reaction temperature, pH, reaction time, churn speed, churner type, etc.).