COSMO Advanced Materials

Leading the Way to Global Excellence

COSMO Advanced Materials

Leading the Way to Global Excellence

/ Products / Toner

Toner

Toner

COSMO AM&T (formerly Saehan Media) launched its toner business in 1976, building on its magnetic media ventures in video and audio. To support this, the company became the first in Korea to develop magnetic iron oxide in 1987. Leveraging this expertise, COSMO AM&T entered the toner industry in 2004 and has since expanded its production capacity to 1,800 tons annually. Currently, the company supplies color toners to over 60 clients worldwide.

R&D

Since 1987, COSMO AM&T has leveraged its know-how in producing 10,000 tons of magnetic iron oxide annually to develop innovative toner products. Initially focused on magnetic component-based toner, the company now manufactures high-speed non-fused color toner, supplying to over 60 customers globally. Looking ahead, COSMO AM&T plans to focus on high-value-added toner products, while also accelerating R&D in other advanced electronic materials.

Cosmo Toner

COSMO AM&T’s toner division focuses on customer-oriented development, reflecting specific regional demands and expanding design compatibility across various models. With 40 years of core toner technology and quality systems, COSMO TONER continues to listen to its customers and aims to deliver globally top-tier products.

Adoption

Since 1938, when Carlson invented the electrophotographic process utilizing triboelectric charging, electrophotography has become an essential technology in offices worldwide—evolving from analog copiers to digital printers, full-color copiers, and now multifunction devices. As these imaging technologies have advanced, toner technology has also progressed in step.

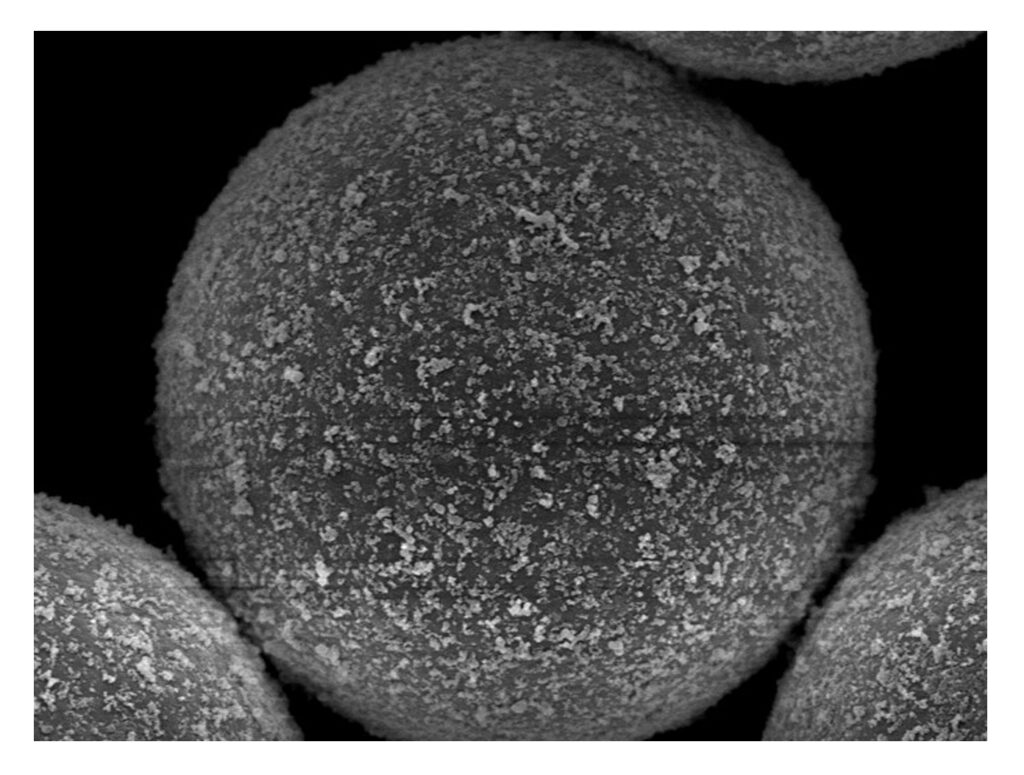

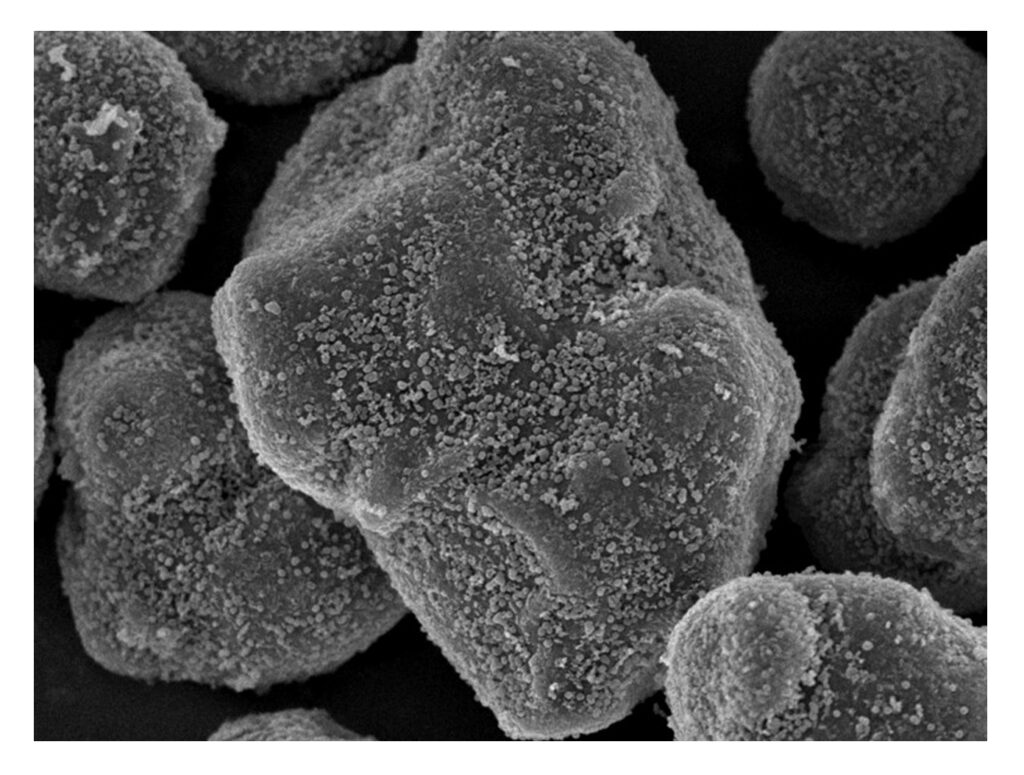

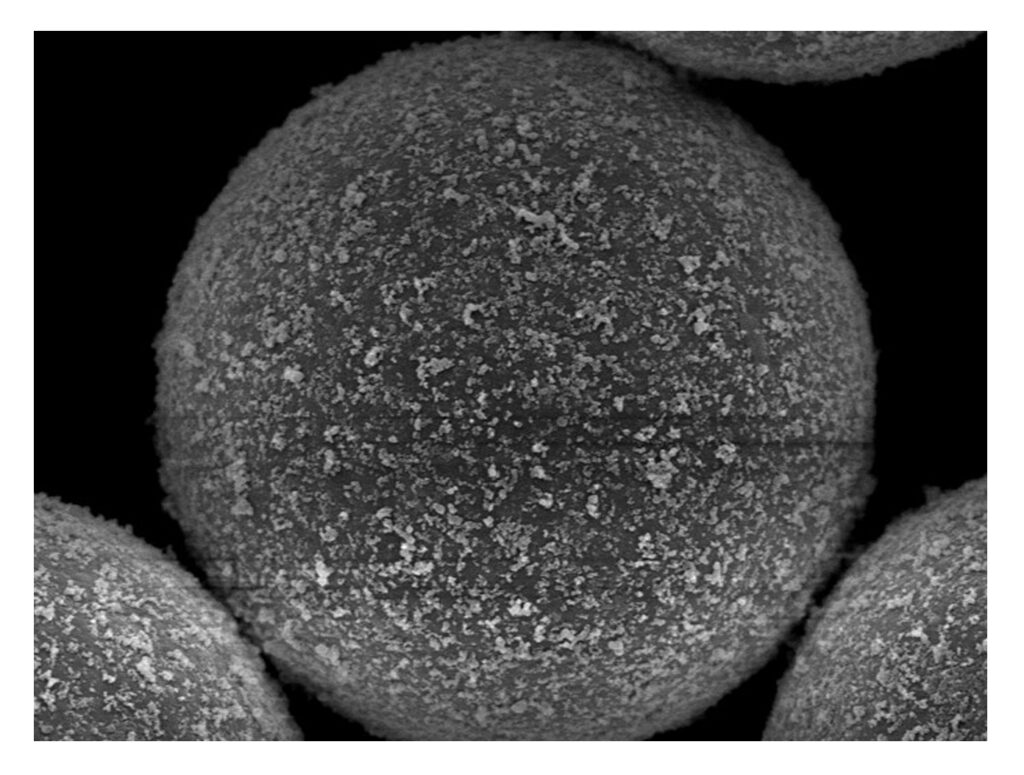

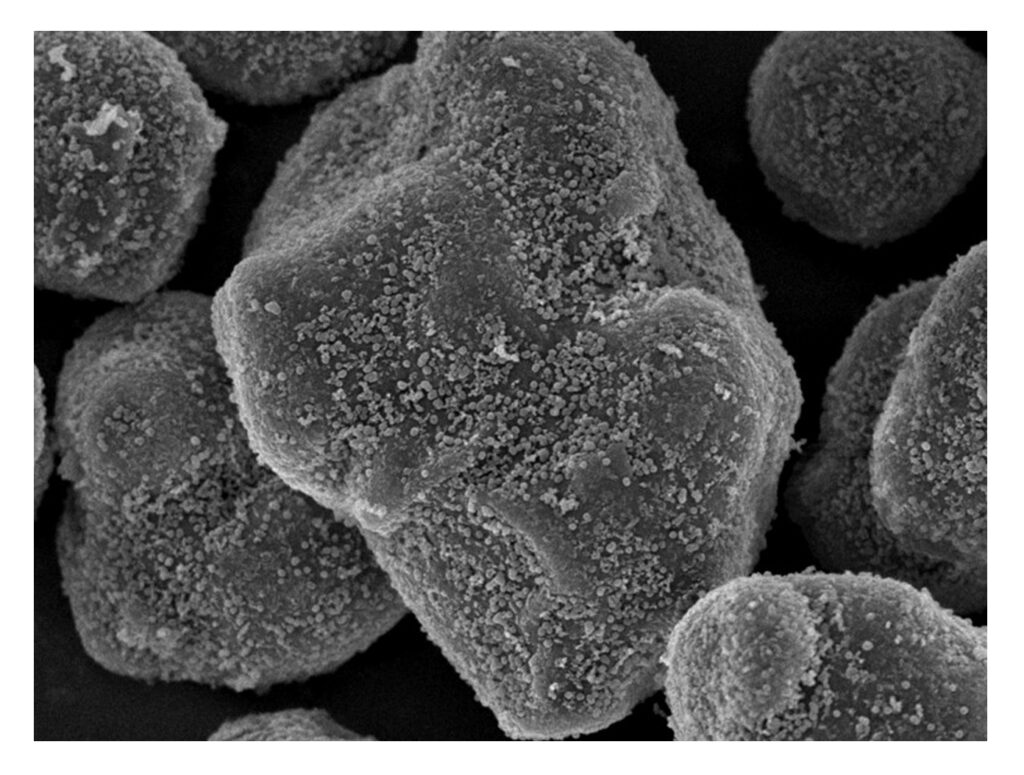

Toner is a fine powder with a particle size of approximately 6 to 15 micrometers, used in copiers and printers. It plays a crucial role in the electrophotographic process by rendering the invisible electrostatic image formed on the photoconductor into a visible image.

Toner Characteristics

Toner powder is designed with an average particle size of 8μm, offering exceptional uniformity and superior flow characteristics.

Its primary ingredients—resin, magnetite, charge control agents, pigments, and wax—can be precisely blended to tailor color performance and functional attributes.

Polymerized Toner

Conventional Toner

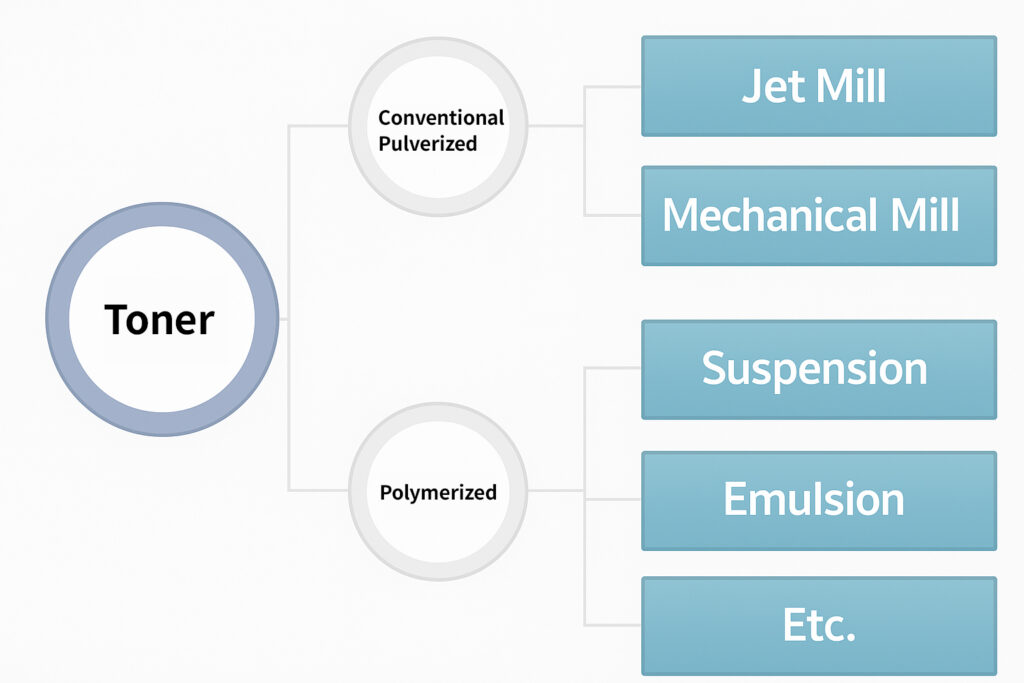

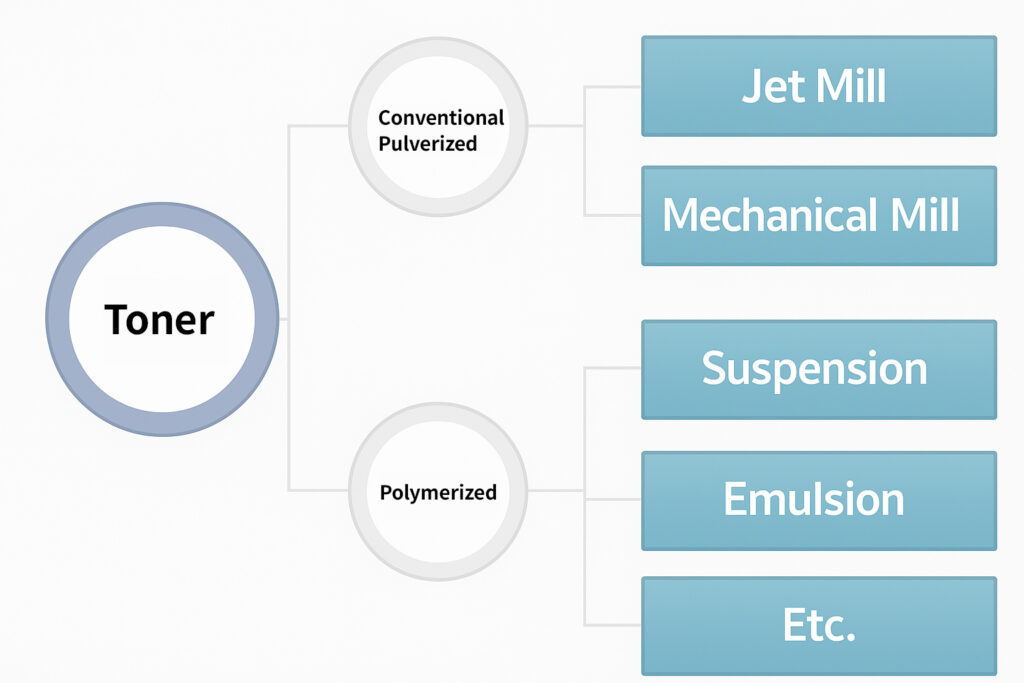

Classification of Toners by Manufacturing Method

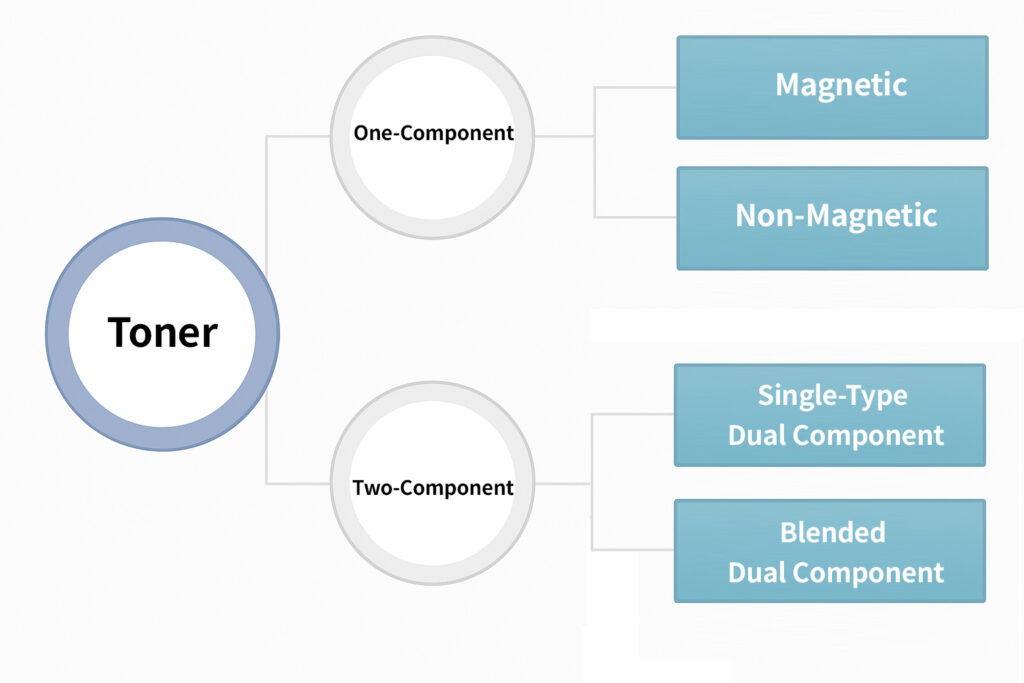

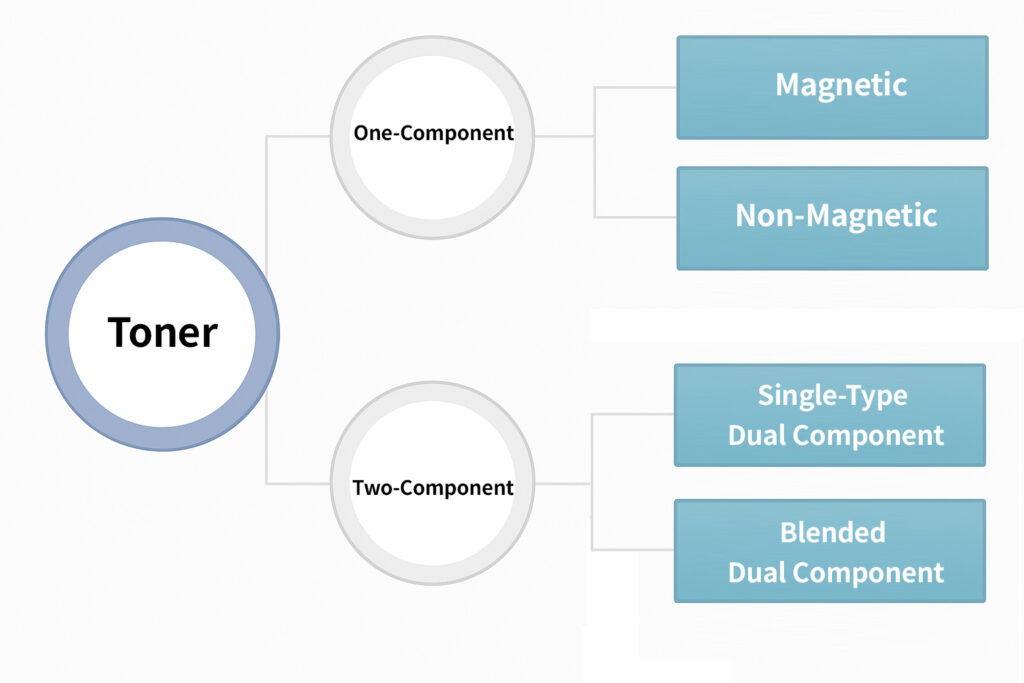

Classification of Toners by Developing Method

Fundamental Principles of the Electrophotographic Process

The electrophotographic imaging process involves a continuous system of steps: toner charging through corona discharge, creation of an electrostatic latent image via exposure on a charged photoconductor, development of the visible image with toner, image transfer onto paper, and heat-pressure fusion for permanent fixation.

① Charging

A uniform electrostatic charge is applied to the surface of the photoreceptor.

① Charging

A uniform electrostatic charge is applied to the

surface of the photoreceptor.

The charge neutralization process eliminates residual potentials from previous imaging steps, thereby optimizing subsequent printing quality.

This process utilizes either contact-based Primary Charge Rollers (PCR) or non-contact corotron systems, depending on the specific application.

② Exposing

The photoreceptor is selectively exposed to laser light to form an electrostatic image.

② Exposing

The photoreceptor is selectively exposed to laser light

to form an electrostatic image.

The desired image is projected onto a photoconductive drum using LED or laser exposure, creating regions of differing electrical potential. This process results in the formation of an electrostatic latent image that serves as the basis for printing.

③ Developing

Toner particles adhere to the electrostatic image, rendering it visible.

③ Developing

Toner particles adhere to the electrostatic image

rendering it visible.

Inside the developing unit, toner particles acquire an electric charge through triboelectric interaction with carrier particles or charging members such as blades. The charged toner is then transferred from the developing roller to the electrostatic latent image on the photoconductor, a process driven by the electrostatic potential difference. At this stage, the latent image on the photoconductor is developed into a visible image.

④ Transferring

The toner image is transferred from the photoconductor to the paper substrate.

④ Transferring

The toner image is transferred from the

photoconductor to the paper substrate.

The toner image developed on the photoconductor is transferred onto paper by means of electrostatic force, resulting in the visible image being formed on the paper.

⑤ Fusing

Heat and pressure are applied to fuse the toner onto the paper surface permanently.

⑤ Fusing

Heat and pressure are applied to fuse the toner on

to the paper surface permanently.

The toner transferred onto paper is typically fused using a combination of heat and pressure. As part of energy-saving initiatives, there is growing demand for toners that can achieve fixation at lower temperatures.

⑥ Cleaning

Any residual toner left on the photoconductor is thoroughly cleaned.

⑥ Cleaning

Any residual toner left on the photoconductor is

thoroughly cleaned.

In the cleaning process, any residual toner remaining on the photoconductor after image transfer is removed—typically using a rubber blade or similar device. Complete removal is essential, as any leftover toner can adversely affect subsequent images.

Black Printer

Color Printer

Black Copier

Color Copier

Toner Business

COSMO AM&T (formerly Saehan Media) launched its toner business in 1976, building on its magnetic media ventures in video and audio. To support this, the company became the first in Korea to develop magnetic iron oxide in 1987. Leveraging this expertise, COSMO AM&T entered the toner industry in 2004 and has since expanded its production capacity to 1,800 tons annually. Currently, the company supplies color toners to over 60 clients worldwide.

R&D

Since 1987, COSMO AM&T has leveraged its know-how in producing 10,000 tons of magnetic iron oxide annually to develop innovative toner products. Initially focused on magnetic component-based toner, the company now manufactures high-speed non-fused color toner, supplying to over 60 customers globally. Looking ahead, COSMO AM&T plans to focus on high-value-added toner products, while also accelerating R&D in other advanced electronic materials.

Cosmo Toner

COSMO AM&T’s toner division focuses on customer-oriented development, reflecting specific regional demands and expanding design compatibility across various models. With 40 years of core toner technology and quality systems, COSMO TONER continues to listen to its customers and aims to deliver globally top-tier products.

Adoption

Since 1938, when Carlson invented the electrophotographic process utilizing triboelectric charging, electrophotography has become an essential technology in offices worldwide—evolving from analog copiers to digital printers, full-color copiers, and now multifunction devices. As these imaging technologies have advanced, toner technology has also progressed in step.

Toner is a fine powder with a particle size of approximately 6 to 15 micrometers, used in copiers and printers. It plays a crucial role in the electrophotographic process by rendering the invisible electrostatic image formed on the photoconductor into a visible image.

Toner Characteristics

Toner powder is designed with an average particle size of 8μm, offering exceptional uniformity and superior flowcharacteristics.

Its primary ingredients—resin, magnetite, charge control agents, pigments, and wax—can be precisely blended to tailor color performance and functional attributes.

Polymerized Toner

Conventional Toner

Classification of Toners by

Manufacturing Method

Classification of Toners by

Developing Method

Fundamental Principles of the Electrophotographic Process

The electrophotographic imaging process involves a continuous system of steps: toner charging through corona discharge, creation of an electrostatic latent image via exposure on a charged photoconductor, development of the visible image with toner, image transfer onto paper, and heat-pressure fusion for permanent fixation.

① Charging

A uniform electrostatic charge is applied to

the surface of the photoreceptor.

The charge neutralization process eliminates residual potentials from previous imaging steps, thereby optimizing subsequent printing quality.

This process utilizes either contact-based Primary Charge Rollers (PCR) or non-contact corotron systems, depending on the specific application.

② Exposing

The photoreceptor is selectively exposed to

laser light to form an electrostatic image.

The desired image is projected onto a photoconductive drum using LED or laser exposure, creating regions of differing electrical potential. This process results in the formation of an electrostatic latent image that serves as the basis for printing.

③ Developing

Toner particles adhere to the electrostatic

image, rendering it visible.

Inside the developing unit, toner particles acquire an electric charge through triboelectric interaction with carrier particles or charging members such as blades. The charged toner is then transferred from the developing roller to the electrostatic latent image on the photoconductor, a process driven by the electrostatic potential difference. At this stage, the latent image on the photoconductor is developed into a visible image.

④ Transferring

The toner image is transferred from the

photoconductor to the paper substrate.

The toner image developed on the photoconductor is transferred onto paper by means of electrostatic force, resulting in the visible image being formed on the paper.

⑤ Fusing

Heat and pressure are applied to fuse the

toner onto the paper surface permanently.

The toner transferred onto paper is typically fused using a combination of heat and pressure. As part of energy-saving initiatives, there is growing demand for toners that can achieve fixation at lower temperatures.

⑥ Cleaning

Any residual toner left on the

photoconductor is thoroughly cleaned.

In the cleaning process, any residual toner remaining on the photoconductor after image transfer is removed—typically using a rubber blade or similar device. Complete removal is essential, as any leftover toner can adversely affect subsequent images.

Black Printer

Color Printer

Black Copier

Color Copier

Company

Products

Sustainability

Media Center

Company Name: COSMO AM&T Co., Ltd. | Business Registration Number: 137-81-01917 | CEO: Dong-Hwan Hong

Head Office: 36, Chungjuhosu-ro, Chungju-si, Chungcheongbuk-do, Republic of Korea

Tel: +82-43-850-1114 | Fax: +82-43-851-9298 | COPYRIGHT © 2025 COSMO AM&T. ALL RIGHTS RESERVED.

Company Name: COSMO AM&T Co., Ltd.

Business Registration Number: 137-81-01917 | CEO : Dong-Hwan Hong

Head Office : 36, Chungjuhosu-ro, Chungju-si, Chungcheongbuk-do, Republic of Korea

Tel: +82-43-850-1114 | Fax: +82-43-851-9298

COPYRIGHT © 2025 COSMO AM&T. ALL RIGHTS RESERVED.

Company Name: COSMO AM&T Co., Ltd.

Business Registration Number: 137-81-01917

CEO: Dong-Hwan Hong

Head Office: 36, Chungjuhosu-ro, Chungju-si

Chungcheongbuk-do, Republic of Korea

Tel: +82-43-850-1114 | Fax: +82-43-851-9298

COPYRIGHT © 2025 COSMO AM&T. ALL RIGHTS RESERVED.

COPYRIGHT(C) 2025 COSMOAMT ALL RIGHTS RESERVED.

No.1 Fiberglass Door

Manufacturer in Korea

DoorCo Korea Co.,LTD

TEL : +82-43-930-0200

FAX : +82-43-930-0201