COSMO Advanced Materials

Leading the Way to Global Excellence

COSMO Advanced Materials

Leading the Way to Global Excellence

/ Products / R&D

R&D

COSMO AM&T R&D Center Shaping the Future

“Driven by a New Frontier Spirit, we are dedicated to developing products that bring us closer to our customers.”

Our R&D Center plays a pivotal role in enhancing competitiveness across existing industries while pioneering advanced materials for display technology, secondary batteries, and digital devices.

By focusing on the evolving needs of our customers, we are committed to continuous R&D investment and innovation.

Moving forward, our researchers will strive to deliver high-value-added solutions that advance customer satisfaction and foster long-term partnerships.

Release films are manufactured by coating one or both sides of a high-performance polyester base film with silicone formulations and inorganic additives such as anti-static agents.

These films exhibit excellent release properties, uniform adhesion, and superior anti-static performance.

Application

These release films feature excellent surface roughness control and thickness uniformity. Their versatility across diverse applications and process conditions makes them ideal for use in industrial and electronic adhesive laminates, anti-static protective layers, and as carrier films in the molding of resin or ceramic sheets.

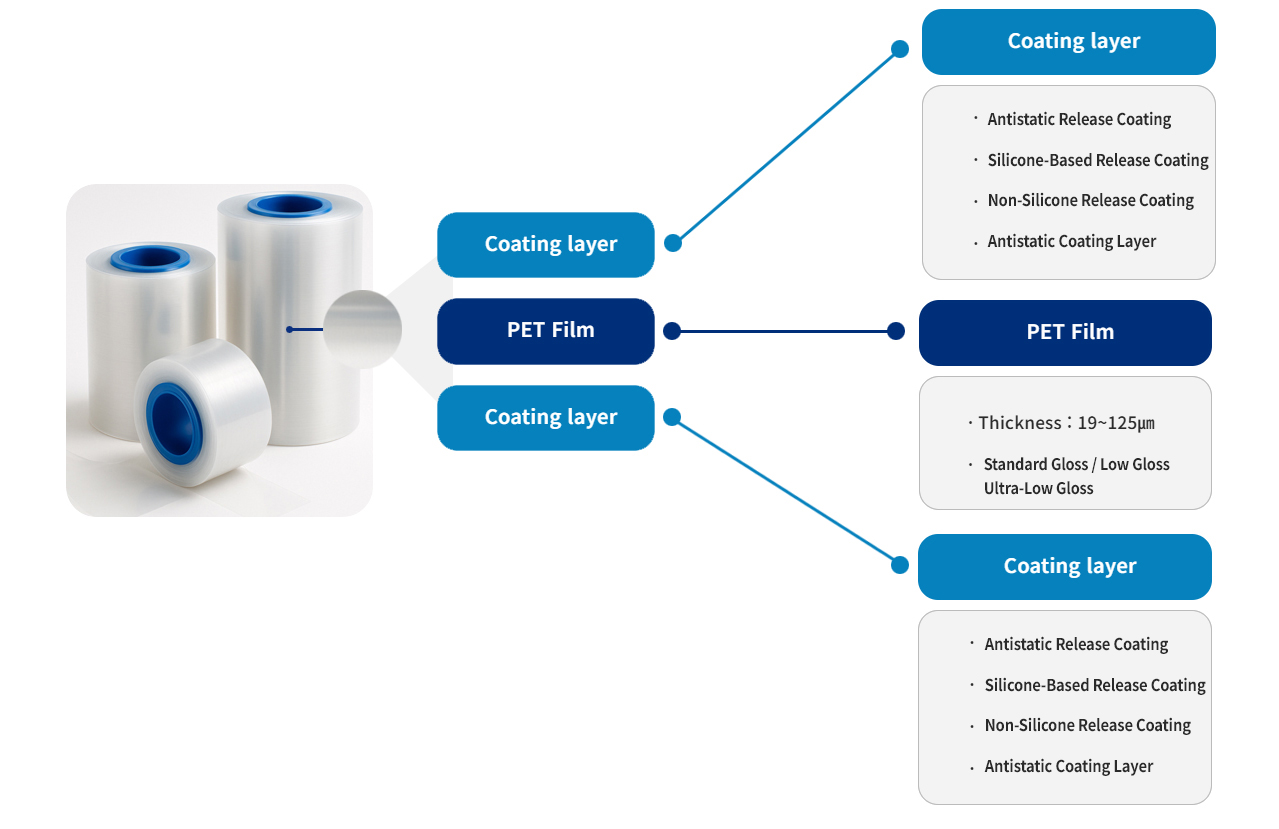

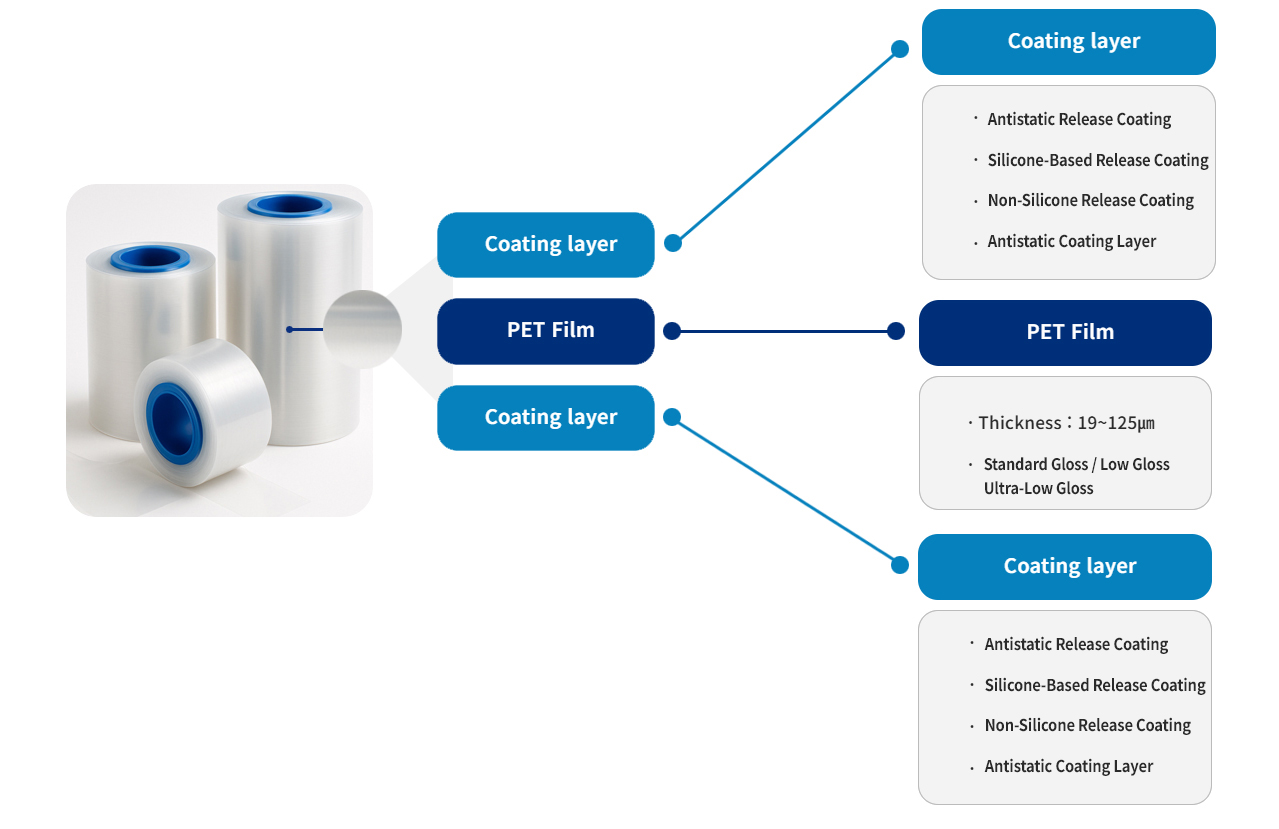

Structure

Depending on customer requirements, the coating layer and PET base film thickness can be customized.

We offer tailored recommendations based on the specific application of the release film.

Cathode Active Materials is an essential material that plays a key role in the charging and discharging of secondary batteries. Currently, the secondary battery market is rapidly growing thanks to the explosive growth of the electric vehicle (xEV) and energy storage system (ESS) markets, and accordingly, the demand for high-performance positive electrode active materials is also increasing. Based on the unique know-how accumulated through lithium cobalt oxide (LCO) technology in the past, COSMO AM&T’s now leading technological innovation by securing NCM-based single crystal technology.

The R&D capability of COSMO AM&T’s the key driving force to lead the secondary battery market in the future. We are focusing our research capabilities on the development of next-generation cathode materials with high voltage and high performance characteristics. In particular, we are presenting new technological standards for the secondary battery industry through innovative research and development such as middle nickel single crystal and high nickel single crystal material technologies to maximize energy density and stability, as well as non-precursive technologies to secure cost competitiveness and environmental sustainability, and LMR (Lithium Rich Manganese-based) materials that achieve high capacity and high stability at the same time.

COSMO AM&T’s will proactively respond to the rapidly changing technical needs of the market through constant R&D investment, contribute to the implementation of sustainable energy solutions, and lead the global anode active material market. will proactively respond to the rapidly changing technical needs of the market through constant R&D investment, contribute to the implementation of sustainable energy solutions, and lead the global anode active material market.

Application

Cathode active materials are broadly applied in compact devices such as smartphones, feature phones, tablet PCs, notebook PCs, digital cameras, MP3 players, and portable game consoles. They are also used in small devices including e-bikes, electric vehicles (xEV), and energy storage systems (ESS).

Product Applications

Precursor materials for lithium-ion battery cathodes are mixed with lithium sources to form active cathode materials.

For LiCoO₂, common precursors include Co₃O₄, Co(OH)₂, and CoOOH.

For Li(NixCoyMnz)O₂ systems, the primary precursor used is NixCoyMnz(OH)₂.

Manufacturing Method

Production is primarily based on co-precipitation.

Using chemical reactors, metal salt solutions are combined with agents such as sodium hydroxide and ammonia to induce co-precipitation.

Depending on reaction parameters—composition, temperature, pH, reaction time, agitation speed, and type of stirrer—various product properties can be achieved.

COSMO AM&T R&D Center Shaping the Future

“Driven by a New Frontier Spirit, we are dedicated to developing products that bring us closer to our customers.”

Our R&D Center plays a pivotal role in enhancing competitiveness across existing industries while pioneering advanced materials for display technology, secondary batteries, and digital devices.

By focusing on the evolving needs of our customers, we are committed to continuous R&D investment and innovation.

Moving forward, our researchers will strive to deliver high-value-added solutions that advance customer satisfaction and foster long-term partnerships.

Release films are manufactured by coating one or both sides of a high-performance polyester base film with silicone formulations and inorganic additives such as anti-static agents.

These films exhibit excellent release properties, uniform adhesion, and superior anti-static performance.

Application

These release films feature excellent surface roughness control and thickness uniformity. Their versatility across diverse applications and process conditions makes them ideal for use in industrial and electronic adhesive laminates, anti-static protective layers, and as carrier films in the molding of resin or ceramic sheets.

Structure

Depending on customer requirements, the coating layer and PET base film thickness can be customized.

We offer tailored recommendations based on the specific application of the release film.

Cathode Active Materials are essential components of secondary batteries, playing a critical role in charge and discharge cycles. The global secondary battery market was valued at USD 14.5 billion in 2013 and is expected to grow at an annual rate of 15.1%. With the expanding demand for electric vehicles (xEV) and energy storage systems (ESS), the market is projected to reach USD 23.6 billion by 2016.

Currently, commercial cathode active materials are classified into LCO, NCA, NMC, LMO, and LFP. Among them, COSMO AM&T’s primary product, LCO (Lithium Cobalt Oxide), is widely used in compact IT applications such as smartphones and tablet PCs. It offers excellent capacity, lifespan, and stability. COSMO AM&T has successfully developed LCO currently used in commercial applications and continues to enhance the material to achieve even higher performance and voltage characteristics.

Application

Cathode active materials are broadly applied in compact devices such as smartphones, feature phones, tablet PCs, notebook PCs, digital cameras, MP3 players, and portable game consoles. They are also used in small devices including e-bikes, electric vehicles (xEV), and energy storage systems (ESS).

Product Applications

Precursor materials for lithium-ion battery cathodes are mixed with lithium sources to form active cathode materials. For LiCoO₂, common precursors include Co₃O₄, Co(OH)₂, and CoOOH. For Li(NixCoyMnz)O₂ systems, the primary precursor used is NixCoyMnz(OH)₂.

Manufacturing Method

Production is primarily based on co-precipitation.

Using chemical reactors, metal salt solutions are combined with agents such as sodium hydroxide and ammonia to induce co-precipitation.

Depending on reaction parameters—composition, temperature, pH, reaction time, agitation speed, and type of stirrer—various product properties can be achieved.

Company

Products

Sustainability

Media Center

Company Name: COSMO AM&T Co., Ltd. | Business Registration Number: 137-81-01917 | CEO: Dong-Hwan Hong

Head Office: 36, Chungjuhosu-ro, Chungju-si, Chungcheongbuk-do, Republic of Korea

Tel: +82-43-850-1114 | Fax: +82-43-851-9298 | COPYRIGHT © 2025 COSMO AM&T. ALL RIGHTS RESERVED.

Company Name: COSMO AM&T Co., Ltd.

Business Registration Number: 137-81-01917 | CEO : Dong-Hwan Hong

Head Office : 36, Chungjuhosu-ro, Chungju-si, Chungcheongbuk-do, Republic of Korea

Tel: +82-43-850-1114 | Fax: +82-43-851-9298

COPYRIGHT © 2025 COSMO AM&T. ALL RIGHTS RESERVED.

Company Name: COSMO AM&T Co., Ltd.

Business Registration Number: 137-81-01917

CEO: Dong-Hwan Hong

Head Office: 36, Chungjuhosu-ro, Chungju-si

Chungcheongbuk-do, Republic of Korea

Tel: +82-43-850-1114 | Fax: +82-43-851-9298

COPYRIGHT © 2025 COSMO AM&T. ALL RIGHTS RESERVED.

COPYRIGHT(C) 2025 COSMOAMT ALL RIGHTS RESERVED.

No.1 Fiberglass Door

Manufacturer in Korea

DoorCo Korea Co.,LTD

TEL : +82-43-930-0200

FAX : +82-43-930-0201